Cov chips semiconductor yog lub hauv paus tseem ceeb ntawm kev siv thev naus laus zis thiab yog ib qho thev naus laus zis tshiab thiab kev lag luam tseem ceeb uas cov teb chaws tab tom sib tw los tsim.Ncuav mog qab zib, ua cov khoom siv tseem ceeb rau kev tsim cov semiconductor chips, ua lub luag haujlwm tseem ceeb heev hauv kev txhim kho Tuam Tshoj txoj kev lag luam semiconductor. Hais txog lub peev xwm tsim wafer, Tuam Tshoj twb tau ua tus thawj coj hauv ntiaj teb, tab sis thaum lub ntiaj teb "kev tsis txaus chip" nce ntxiv, nws yuav ua rau muaj peev xwm nthuav dav ntxiv.

1. Keeb Kwm ntawm Qhov Project

Ib lub tuam txhab me ntawm ib pawg lag luam semiconductor hauv tebchaws, ua tus thawj coj hauv kev lag luam cov ntaub ntawv hluav taws xob hauv tebchaws, cog lus rau kev tshawb fawb thiab kev txhim kho, kev tsim cov ntaub ntawv semiconductor, cov ntaub ntawv tshwj xeeb hauv hluav taws xob, cov khoom siv semiconductor thiab lwm yam thev naus laus zis. Cov khoom tseem ceeb yog semiconductor zone melting single crystal silicon wafer, nrog rau peb lub zog thoob ntiaj teb thiab kev lag luam hauv tebchaws ntawmtshaj 80%.

Txhawm rau kom ua kom muaj peev xwm nthuav dav sai dua, lub tuam txhab tau nqis peev kwv yees li $ 3 billion los pib tsim kho qhov project tsim thiab tsim cov silicon wafer loj rau cov integrated circuits hauv Yixing City, Jiangsu Province. Theem thib ob ntawm qhov project tau pib xyoo 2021, ua raws li lub tswv yim siab heev ntawm "Kev Lag Luam 4.0" thiab npaj siv kev tsim khoom ntse thoob plaws hauv kab kom ua tiav kev ua haujlwm tsis siv neeg, kev qhia xov xwm, thiab kev tsim kho ntse ntawm lub chaw ua haujlwm. Tom qab ua tiav, tag nrho cov peev xwm tsim khoom yuav yog 220000 8-nti epitaxial wafers, 200000 12-nti polished wafers, thiab 150000 12-nti epitaxial wafers ib hlis, dhau los ua lub hauv paus tsim khoom silicon wafer nrog cov txiaj ntsig thoob ntiaj teb. Yog li ntawd, hais txog pawg neeg lub chaw khaws khoom ntse,ROBOTECH tau txhim kho qib kev txawj ntse, kev siv cov ntaub ntawv, thiab kev ua haujlwm tsis siv neeg ntawm nws lub hauv paus tsim khoom los ntawm kev siv cov txheej txheem khaws cia ntse heev..

2. Txoj Haujlwmpkev ua liaj ua teb

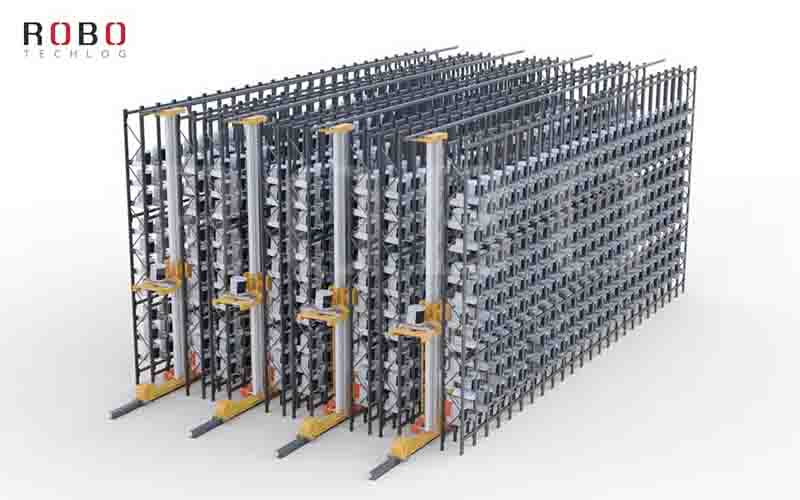

ROBOTECH tau siv tag nrho 6m qhov chaw ntsug ntawm nws lub hauv paus tsim khoom thiab npaj ib4-txoj kab thawv hom tsis siv neeg lub tsev rau khoomrau kev nkag mus rau cov khoom lag luam semiconductor wafer, uas tuaj yeem pab txhawb tag nrho ntau dua2000 qhov chaw cia khoom, ua kom muaj peev xwm khaws cia ntawm cov wafers zoo duaVim tias lub wafer nyob rau hauv daim ntawv ntawm ib daim ntawv, nws tus neeg nqa khoom siv lub thawv yas tshwj xeeb 330 * 330 * 300 pob tshab rau kev nkag mus rau lub wafer yooj yim, nrog rau qhov siab tshaj plaws ntawm 50kg.Daws qhov teeb meem ntawm cov txheej txheem khaws cia wafer nyuaj thiab kev siv qhov chaw tsawg hauv cov tsev khaws khoom ib txwm muaj, ua tiav kev txhim kho ob npaug hauv kev siv qhov chaw thiab kev ua haujlwm zoo.

• Zebra series stacker crane system

• 100m/feeb & 24-teev kev tsim khoom rhythm & 63P/h ib lub voj voog

Hais txog kev ua haujlwm zoo, ROBOTECH xaiv covzebra series stackerlub cranelub kaw lusrau cov khoom siv dynamic siab, nrog rau qhov ceev kab rov tav ntawm100m/feeb, uas ua tau raws li qhovLub sijhawm tsim khoom 24 teevntawm lub hauv paus tsim khoom, thiab qhov kev cia khoom zoo tuaj yeem ncav cuag63P/teev ib lub voj voog.

3. Tsis ntshai kev cov nyom, kev tsim kho tshiab raws li koj xav tau

•Ensure plua plav thiab poob siab tsis kam

•Kev kho kom haum tsis yog tus qauv

•Ulub cuab yeej ntsuas ltrasonic

•Ttus neeg nqa khoom tau muab tso rau ntawm lub kaum sab xis ntawm 5 degrees ntawm cov txee thiab rab rawg.

Kev Sib Tw 1

Cov yam ntxwv ntawm kev khaws cia ntawm semiconductor wafers yogxyuas kom meej tias muaj plua plav thiab kev poob siab tiv taus, txwv tsis pub nws yooj yim ua rau puas tsuaj rau cov wafers uas tsis muaj zog. Raws li qhov no, ROBOTECH tau hloov kho cov qauv kho tshuab ntawm lub stacker crane komkev hloov kho tsis raws li tus qauvPiv txwv li, cov hlau hlau aluminium alloy hauv av siv hloov cov hlau hlau ib txwm muaj, cov kem hlau aluminium alloy txias uas muaj zog siab siv hloov cov kem hlau, cov log uas muaj roj hmab siv hloov cov log hlau, Kev siv txoj siv sia siv hloov cov hlua hlau, thiab cov npog tiv thaiv plua plav ntxiv rau lub platform thauj khoom.Txij thaum pib tsim cov khoom siv, qhov cuam tshuam ntawm hmoov av thiab kev co rau cov khoom tau raug txo qis, qhov kev pheej hmoo ntawm kev ua qias tuaj hauv lub chaw ua haujlwm tsis muaj hmoov av tau raug txo qis,thiab cov qoob loo tau zoo dua. Qib kev huv si tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm ib puag ncig ntawm Chav Kawm 1000.

Kev Sib Tw 2

Vim yog lub thawv yas pob tshab ntawm lub wafer carrier, cov photoelectric sensors ib txwm siv tsis tau rau kev ntes cov khoom thauj. ROBOTECH tsim tshiab ib qholub cuab yeej ultrasonic sensorrau kev kuaj pom cov khoom thauj, uas tuaj yeem ntes tau qhov xwm txheej ntawm cov khoom ntawm cov txee thiab pallets. Thiab nws muaj lub koob yees duab thiab lub vijtsam ua haujlwm tes kom ua tiav qhov pom tseeb thiab taug qab ntawm txhua yam khoom siv thoob plaws hauv tag nrho cov txheej txheem, thaum tseem daws teeb meem thiab daws qhov yuam kev hauv txoj hauv kev yooj yim dua.

Kev Sib Tw3

Yuav kom tiv thaiv tau lub wafer kom tsis txhob swb ntawm lub cab kuj,tus neeg nqa khoom tau muab tso rau ntawm lub kaum sab xis ntawm 5 degrees ntawm cov txee thiab rab rawg.Qhov kev tso qhov chaw siab thiab kev sib tsoo ruaj khov yog ua tiav los ntawm kev ntxig qhov hauv qab ntawm lub thawv wafer rau hauv peb lub pins ntawm lub cuab yeej tshwj xeeb rau kev teeb tsa lub platform thauj khoom hauv huab cua rau kev khaws cia. Tom qab kev sim rov ua dua, qhov tseeb qhov chaw kawg tau mus txog.± 2 hli, thiab qhov kev du ntawm kev sib tsoo tau mus txog99.99%Tsis tas li ntawd xwb, cov khoom siv tau txais ntau yam khoom siv sib txuas, ua kom zoo dua qhov dav davkev ruaj khov thiab kev nyab xeeb.

Ua ib tug kws tshaj lij hauv kev daws teeb meem kev khaws cia khoom tsis siv neeg, ROBOTECH tau tsim cov kev daws teeb meem logistics ntserau cov ntaub ntawv wafer uas tsis muaj kuab paug thiab taug qab tau hauv lub sijhawm tiag tiag, raws li cov khoom siv siab heev thiab cov txheej txheem ua tiav.

Qhov kev ua tiav ntawm qhov project no qhia tau tiaskev tshawb pom zoo hauv kev cia khoom semiconductor wafer automated, thiab kuj txhais tau tiasROBOTECH yuav nkag mus rau hauv kev lag luam semiconductor, txhawb kom cov tuam txhab semiconductor muaj kev daws teeb meem automation txawj ntse. Yav tom ntej, ROBOTECH yuav txuas ntxiv tshawb nrhiav, khaws cov kev paub txog kev lag luam, txhim kho kev siv cov peev txheej, thiab ua tiav kev txhim kho kev ua haujlwm zoo.

NanJing Inform Storage Equipment (Group) Co., Ltd

Xov tooj ntawm tes: +86 25 52726370

Chaw nyob: No.470, Yinhua Street, Jiangning District, Nanjing Ctiy, Suav teb 211102

Lub Vas Sab:www.informrack.com

Email:[email tiv thaiv]

Lub sijhawm tshaj tawm: Plaub Hlis-11-2023